PPGI and PPGL Steel Sheets: What’s the Difference?

- Share

- From

- JUNNAN NEWS

- publisher

- Gloria

- Issue Time

- Sep 6,2024

Summary

Working with an experienced industrial adhesives and coil coating supplier will help you to understand your options in the various coatings available for prepainted metal.

junnan steel is your best choice

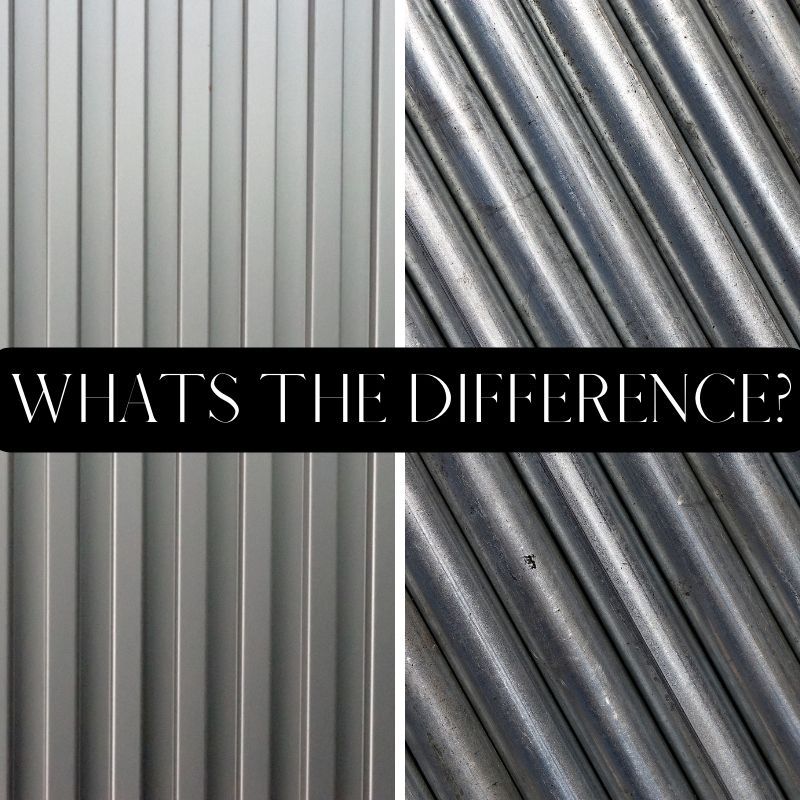

Pre-Painted Galvanized Iron Steel, also called PPGI, and Pre-Painted Galvalume Steel, PPGL, are two different types of color coated steel. Both PPGI and PPGL are used in a wide range of industries such as construction, transportation, and the appliance industry. They are both very similar but still have unique differences.

Different Type of Substrate

Galvanized steel, PPGI, is coated completely with zinc, while Galvalume steel, PPGL, is coated with aluminum, zinc, and a small amount of silicone. This provides superior corrosion resistance and durability over the typical galvanized coating. This is the biggest difference between PPGI steel and PPGL, which is the reason for the differences in many features such as weight, product life, appearance, price, and applications.

Weight Difference of PPGI vs PPGL

Because the specific weight of aluminum is less than the specific weight of zinc, the aluminum zinc coating on PPGL will weigh less with the same coating thickness. Which also means that the Al-Zn coating, with the same weight, can cover 3% more space than PPGI.

Service Life

Both zinc and the aluminum zinc coating help to protect metal against rusting to prolong product service life. With PPGI, when the zinc coating corrodes, the base metal will become damaged. A galvanized PPGI sheet may last approximately 10 to 15 years.

With the aluminum zinc alloy on PPGL, the aluminum rich material will corrode slowly while the zinc rich portion will corrode preferentially. This provides added corrosion resistance over strictly the zinc coating of PPGI. PPGL can last up to three times longer than PPGI.

Difference in Appearance

The PPGL surface will appear to be smoother than the surface of PPGI. Because aluminum has better adhesion properties than zinc, PPGL may not require the same pretreatment for painting as galvanized sheets require.

Heat Tolerance and Erosion

PPGL offers better heat resistance than PPGI, with the ability to withstand temperatures up to 315°C. Because PPGL provides improved corrosion resistance with a dense layer of aluminum the base metal is further protected against erosion. The cut edge of PPGL is less protected, however, due to the honeycomb structure of the coating which does not sufficiently protect exposed edges. A coating can be applied to these exposed edges for added protection.

Applications for Both PPGI and PPGL

Both PPGI and PPGL are used in various roofing and wall paneling applications. Because PPGL better corrosion resistance it is more suitable for harsh outdoor environments such as coastal areas with exposure to seawater. PPGL also provides excellent heat resistance which makes it a popular material for ovens and chimney pipes.

Difference in Price

The price for PPGL is typically slightly more than PPGI due to added performance and fewer manufacturers.