Galvanized wire

- Share

- From

- JUNNAN STEEL NEWS

- publisher

- Gloria Wong

- Issue Time

- Mar 10,2017

Summary

Galvanized wire with high quality low carbon steel wire rod processing, is of high quality low carbon steel, after drawing molding,

Galvanized wire with high quality low carbon steel wire rod processing, is of high quality low carbon steel, after drawing molding, pickling, annealing, galvanizing. The cooling process of the processing of the. Galvanized wire is divided into hot dip galvanized wire and cold galvanized wire (galvanized wire).

Production process: it uses the high quality low carbon steel wire rod processing, is of high quality low carbon steel, after drawing molding, pickling, annealing, galvanizing. The cooling process and processing.

Features: galvanized wire with good toughness and elasticity, the highest amount of zinc can reach 300 grams / square meter. With zinc coating thickness, corrosion resistance and other characteristics.

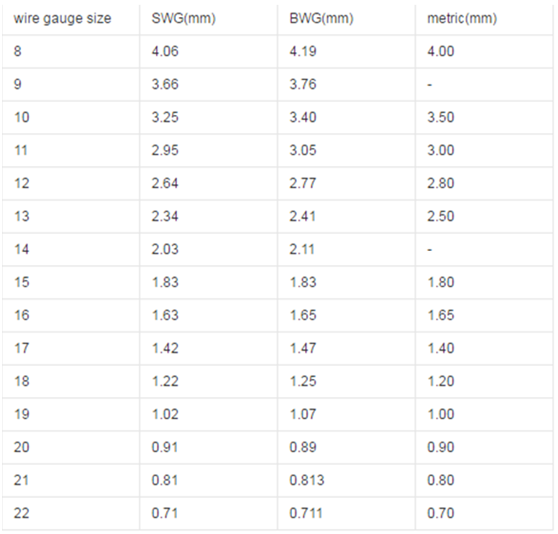

Galvanized wire specifications are as follows:

Application range of hot dip galvanizing:Because of the thicker coating, the hot-dip galvanizing has better protective performance than the zinc plating, so it is an important protective coating for the steel parts in the harsh working environment. Hot dip galvanized products in chemical equipment, petroleum processing, marine exploration, metal structure, power transmission, shipbuilding and other industries has been widely used in fields such as agriculture, irrigation, pesticides and greenhouse construction such as water and gas transportation, wire tube, scaffolding, bridge, highway guardrail etc., is now a large number of being used.